Camper Trailer Shock Absorbers

Camper Trailer Shock Absorbers

Introducing our premium collection of Shock Absorbers, design specifically for off-road Camper Trailers and Caravans.

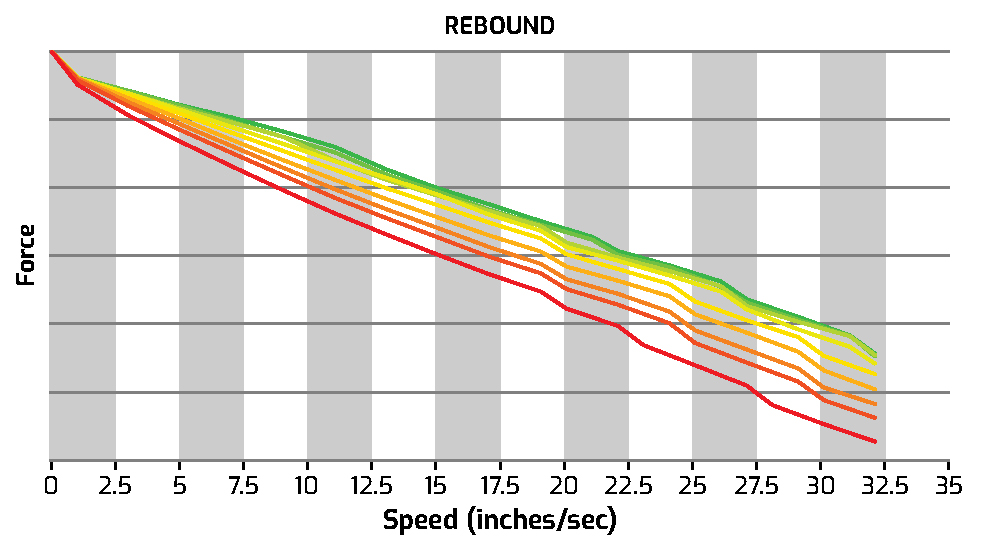

Building upon the robust foundation established by our market-leading 4x4 shock absorbers, this new line includes the cutting-edge Twin Tube Nitro Gas and MRR 3-Way Adjustable models. These shock absorbers have been developed using the proven technology of our trailblazing designs, ensuring each product offers exceptional durability and performance.

Designed and tested in Australia, these shock absorbers are engineered to withstand the toughest global conditions, guaranteeing reliability and enhanced functionality across diverse environments. Whether you’re planning an upgrade to your current system or aiming to refine the handling characteristics of your Camper Trailer or Caravan, our range is meticulously configured to meet your specific requirements.

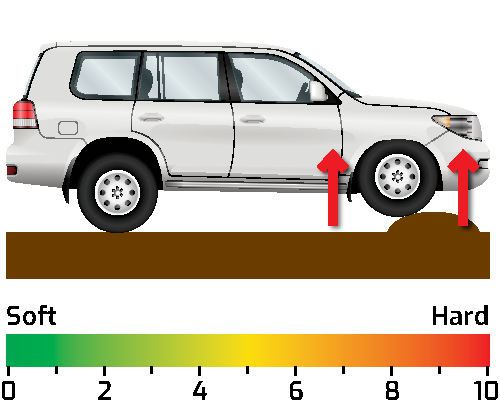

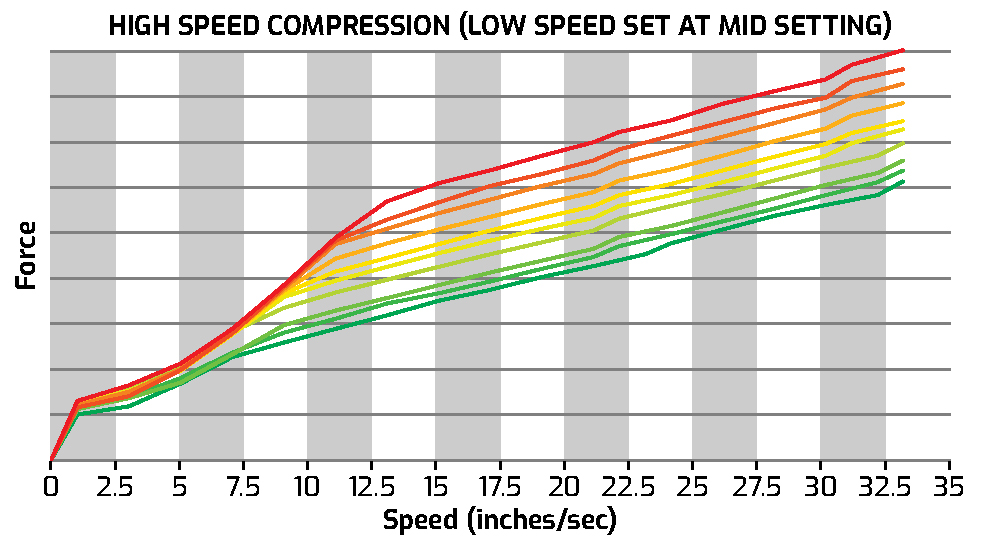

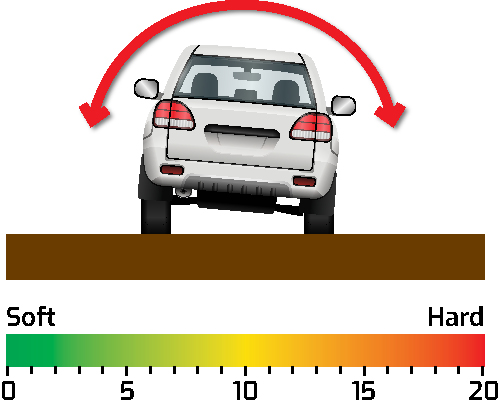

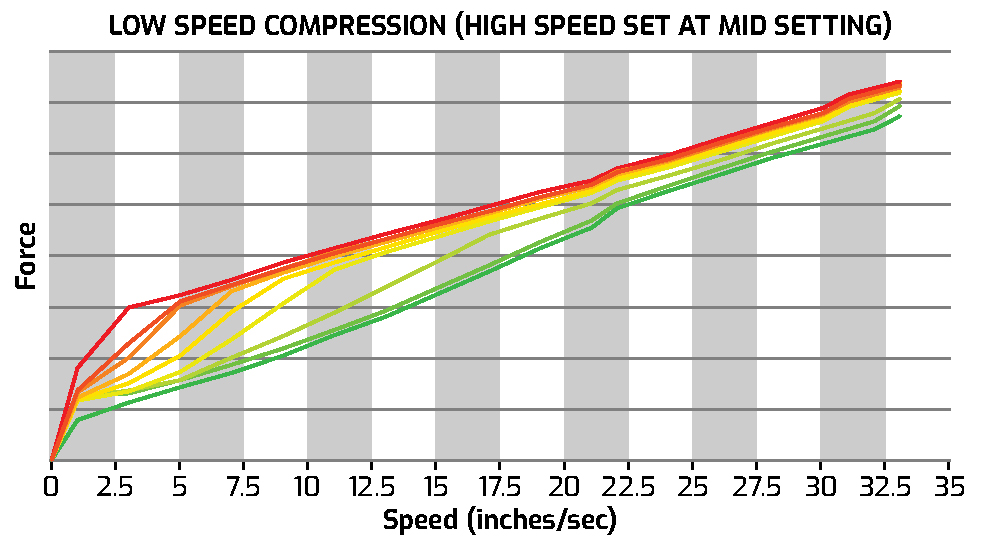

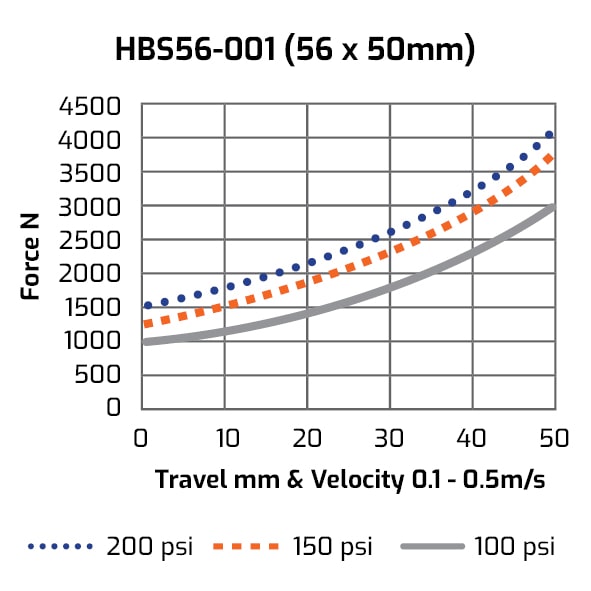

Our Twin Tube Nitro Gas Shock Absorbers offer superior absorption and consistent performance under extreme conditions, while the MRR 3-Way Adjustable Shock Absorbers provide customizable settings that cater to varying terrains and personal preferences. Together, they form a comprehensive suite of solutions that promise to elevate your off-road experience, providing stability, comfort, and control, to take you wherever you want to go—effortlessly and efficiently.

Explore our new range and discover how Dobinsons Spring & Suspension’s innovative technology can transform your next outdoor adventure.

| Item Title | Part Number | Extended inch/mm) |

Compressed (inch/mm) |

Reservoir Length (inch/mm) |

Travel Length (inch/mm) |

Hose Length (inch/mm) |

Rod Diameter (mm) |

|---|---|---|---|---|---|---|---|

GS97-560 |

GS97-560 |

14.8/377 |

9.9/253 |

N/A |

4.8/124 |

N/A |

18 |

GS97-561 |

GS97-561 |

17.9/457 |

11.6/296 |

N/A |

6.3/161 |

N/A |

18 |

MRA97-A561 |

MRA97-A561 |

17.9/457 |

11.7/299 |

7.8/200 |

6.2/158 |

9.8/250 |

22 |

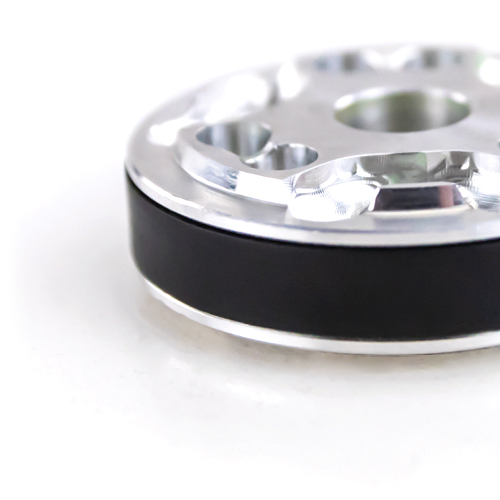

Mounting configuration – supplied with both 16 x 36mm wide rubber and additional 12mm x 36mm wide sleeved bush

-

FIND A STOCKIST

Find your nearest store for expert assistance and advice.

-

CATALOGUES

Looking for a specific part, browse our catalogues. -

CONTACT US

Can't find what you're looking for?

Contact us today.

SHOCK ABSORBERS

Each Dobinsons shock absorber is designed specifically for the vehicle and application and is designed to perform best when matched with Dobinsons Coil Springs.