Coil Springs

Dobinsons Spring & Suspension™ proudly manufacture the highest quality replacement coil springs for many different applications to ISO9001:2008 international quality standards from their state of the art manufacturing facility in Central Queensland, Australia.

WORLDS LARGEST

RANGE OF COIL SPRINGS

Dobinsons™ proudly boast one of the worlds largest range of coil springs including raised height and heavy duty 4wd springs, lowered performance passenger car springs, O.E. replacement springs and heavy duty springs for commercial vehicles.

As Dobinsons™ coil springs are manufactured in-house, Dobinsons™ can manufacture smaller quantities and in most cases there are many different coil spring options available for your vehicle. This ensures the customer receives the best spring to suit their application and avoids a “One Size Fits All” scenario, especially important when selecting the correct spring rates and ride heights.

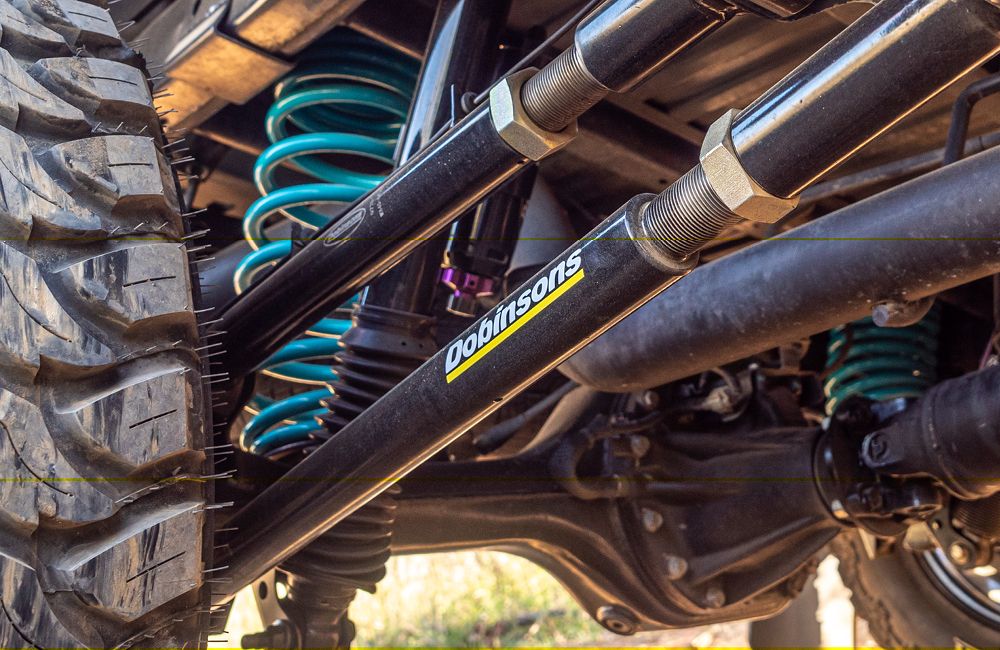

When matched with a set of corresponding Dobinsons™ Shock Absorbers, Dobinsons™ can provide you with unrivalled performance and handling.

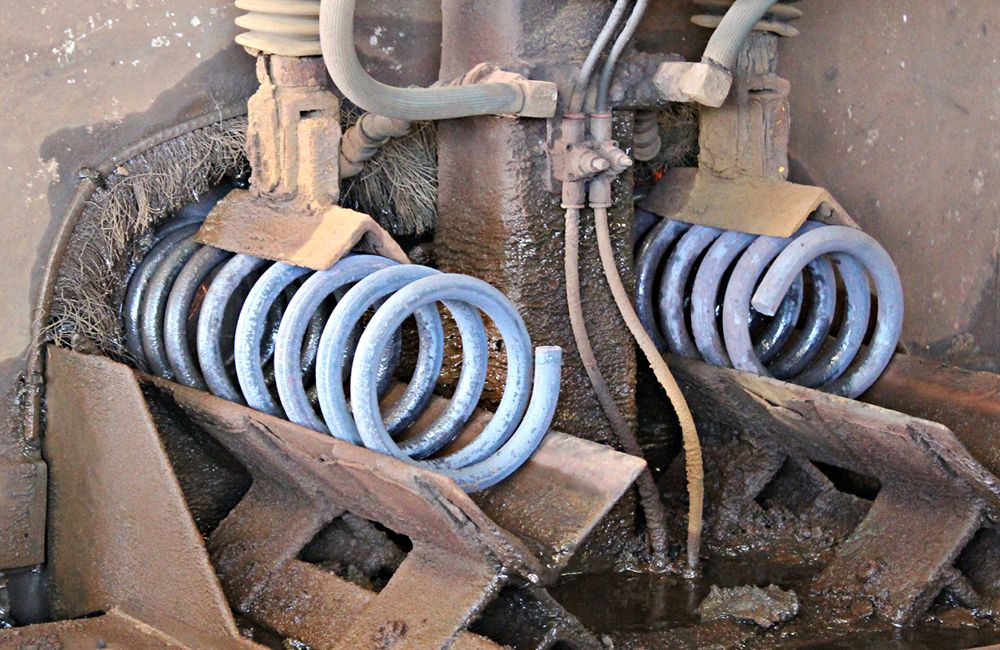

THE LATEST TECHNOLOGY

Dobinsons new coil spring cold roller is the latest addition to the coil spring manufacturing process.

Cold rolling coil springs dramatically decreases production time without compromising strength or durability, maintaining the high quality you expect from Dobinsons.

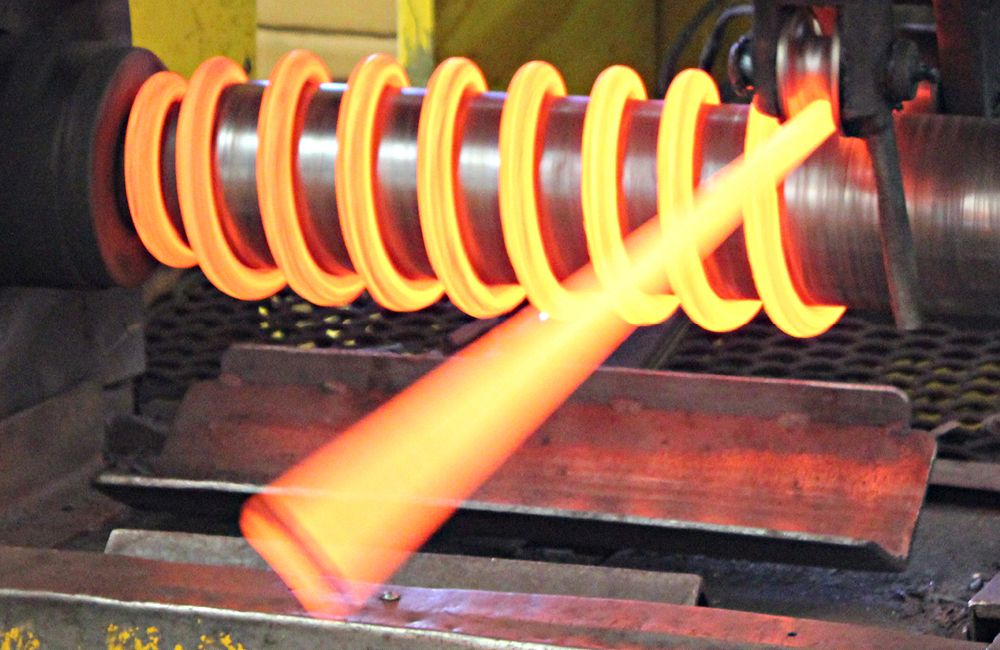

STATE OF THE ART HEAT TREATMENT

Heat treatment is one of the most important steps in the coil spring manufacturing process.

All Dobinsons coil springs are ‘hot wound’ and the hardening and tempering of our coil springs is completed by an extremely precise electronically controlled furnace to eliminate breakage and sagging.

FORMED ON PRECISION MANDRELS

Each coil spring is precisely wound by a programmable logic computer to achieve perfect pitch. This precision is extremely important when manufacturing variable and progressive rate coil springs.

PRECISE END CONFIGURATIONS

Engineered coil ends are designed to fit directly into the original vehicle mounting points without any modification.

POWDER COAT FINISH

A durable powdercoat finish provides extreme protection against the elements.

SHOCK ABSORBERS

Each Dobinsons shock absorber is designed specifically for the vehicle and application and is designed to perform best when matched with Dobinsons Coil Springs.