Bull Bars

BULL BARS

Manufactured from high quality structural steel, Dobinsons Bull Bars are CNC cut, bent and welded for accurate fitment and optimum strength and durability.

CLASSIC BLACK

Perfect for tradies, commercial vehicles and 4x4 owners that want a great looking Bull Bar filled with features, all for a great price.

CLASSIC BLACK DELUXE

For 4x4 owners who are after a tougher look, this Bull Bar provides all the features plus 100mm fog lights.

STAINLESS LOOP DELUXE

When looking for an up-market, prestigious Bull Bar, you can’t go past the Stainless Loop Deluxe featuring all the Dobinsons features plus 100mm fog lights.

Dual Aerial Mounts

Durable Satin Black Powder Coat Finish

Reinforced Bull Bar Wing Sections

Driving Light Mounts

Split Upper & Lower Centre Plate

*Excludes Classic Black Models

LED Indicator & Park Lights

HB4 100mm Fog Lights*

Polyurethane Bumper Overiders

Airbag & Winch Compatible

Dual Reinforced Hi‑Lift Jacking Points

More features:

-

Seperate winch cradle to chassis mounting system allows excess weight and load to be supported directly by the chassis

-

3mm Thick Main Body

-

4mm + 5mm Thick Bracketry

-

1.6mm Bash Plates

-

51mm Upper loops on Classic Black and Classic Black Deluxe (60mm Landcruiser 200 Series)

-

76mm centre loop and 51mm side loops on Stainless Loop Deluxe models

Under Body Protection

Most Dobinsons Bull Bars are also equipped with centre and side protection plates for the underside of the Bull Bar.

A crucial feature to help protect vital vehicle components when off-road driving.

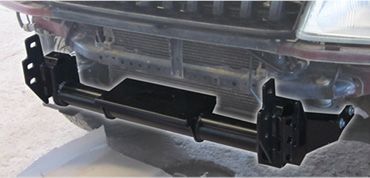

Chassis Mounting System

Separate winch cradle to chassis mounting system allows the additional weight of the wing and winching load to be supported directly by the chassis.

NOTE:

Classic Black and Classic Black Deluxe Bull Bars are supplied with a black finish. Stainless Loop Deluxe Bull Bars are supplied with a black finish and stainless steel loops. Colour matching can be performed by your local automotive spray painter.

Due to the additional weight when fitting a Bull Bar and/or Winch, the vehicle’s ride height will be lowered. Dobinsons Spring & Suspension suggest replacing the springs with a matched pair of springs to suit the requirement.

CNC CUTTING

CNC Laser Profile Cutting ensures perfect accuracy and consistent quality every time without causing unwanted heat distortion.

HYDRAULIC SHEET BENDING

CNC Hydraulic sheet bending machines ensures that the bull bar corner folds are accurate every time without deviation.

LOOP MANDRELS

The tube loops in Dobinsons Bull Bars are made from tube with up to 2.0mm wall thickness* and are bent using CNC Mandrel Bending for uniform shape and wall thickness.

ACCURATE WELDING

Computer programmed robotic welders are used for repetitive intricate welding joins to improve efficiency and accuracy.

JIG ASSEMBLED

All Bull Bars are jig assembled, hand tack welded and then finish welded to ensure accuracy and perfect fitment of each Bull Bar.

CHEMICALLY CLEANED

All Bull Bars are first chemically cleaned, followed by zinc phosphate pre-treatment then powder-coated satin black for a high quality, corrosion resistant aesthetic finish.

Dobinsons Bull Bar Fitment

Everest - UA - Suits 4x4 & 4x2 (Suits Models Fitted With Tech Pack Frontal Vehicle Awareness & Collision System) | 10/2015 to Mid 06/2018 | BB = Requires Bumper Cut | BU19-5543 | BU19-37102Superceded once stock is exhausted, please see specific vehicle page | ||

Everest - UA - Suits 4x4 & 4x2 (Suits Models Fitted Without Tech Pack Frontal Vehicle Awareness & Collision System) | 10/2015 on | BB = Requires Bumper Cut | BU19-5551 | BU19-5726 | BU19-37091Discontinued once stock is exhausted | |

Everest - UA - Suits 4x4 (Suits Models Fitted Without Tech Pack Frontal Vehicle Awareness & Collision System) | 06/2018 on | BB = Requires Bumper Cut | BU19-5551 | BU19-5726 | BU19-37091Discontinued once stock is exhausted | |

Everest - UB, Next Gen - Suits 4x4 | 2022 on | BB = Requires Bumper Cut | BU19-5569 | BU19-5746 | ||

Ranger - Next Gen, RA, PU, T6.2 - Suits 4x4 | 2022 on | BB = Requires Bumper Cut | BU19-5568 | BU19-5745 | ||

Ranger - PJ, PK - Suits 4x4 & 4x2 | 2007 to 09/2011 | FF = Suits Flared Models | BB = Requires Bumper Cut | BU19-3524 | BU19-36761Discontinued once stock is exhausted | |

Ranger - PX / T6 (Pre-Facelift Model) - Suits 4x4 & 4x2 (Does Not Suit Face-Lifted Models) | 2011 to 09/2015 | BU19-5525 | BU19-5686 | |||

Ranger - PX / T7 MKII (Facelift Models) - Suits 4x4 & 4x2 (Suits Models Fitted With Tech Pack Frontal Vehicle Awareness & Collision System) | 10/2015 to Mid 06/2018 | BB = Requires Bumper Cut | BU19-5543 | BU19-37102Superceded once stock is exhausted, please see specific vehicle page | ||

Ranger - PX / T7 MKII (Facelift Models) - Suits 4x4 & 4x2 (Suits Models Fitted Without Tech Pack Frontal Vehicle Awareness & Collision System) | 10/2015 on | BB = Requires Bumper Cut | BU19-5551 | BU19-5726 | BU19-37091Discontinued once stock is exhausted | |

Ranger - PX MKIII / T7 - Suits 4x4 (Suits Models Fitted With & Without Tech Pack Frontal Vehicle Awareness & Collision System) | 06/2018 on | BB = Requires Bumper Cut | BU19-5551 | BU19-5726 | ||

Ranger - PX MKIII / T7 - Suits 4x4 (Suits Models Fitted Without Tech Pack Frontal Vehicle Awareness & Collision System) | 06/2018 on | BB = Requires Bumper Cut | BU19-37091Discontinued once stock is exhausted |

Colorado - RC (TFS-85 / TFR-85) - Suits 4x4 & 4x2 | 2008 to 06/2012 | FF = Suits Flared Models | BB = Requires Bumper Cut | BU21-3514 | BU21-36641Discontinued once stock is exhausted | |

Colorado - RG - Suits 4x4 & 4x2 | 06/2012 to 08/2016 | BB = Requires Bumper Cut | BU21-5532 | BU19-5687 | ||

Colorado - RG - Suits 4x4 & 4x2 (For LTZ Models Fitted With Front Sensors, Adaptor Kit SG80-550K Must Be Used) | 07/2016 | BB = Requires Bumper Cut | BU21-5544 | BU21-5712 | BU21-37151Discontinued once stock is exhausted | |

Colorado 7 / Trailblazer - RG - Suits 4x4 & 4x2 (Initial Release) | 2012 to 06/2016 | BB = Requires Bumper Cut | BU21-5532 | BU19-5687 | ||

Colorado 7 / Trailblazer - RG - Suits 4x4 & 4x2 (Facelift Models) | 07/2016 on | BB = Requires Bumper Cut | BU21-5544 | BU21-5712 | BU21-37151Discontinued once stock is exhausted | |

Rodeo - RA (TFR-77) - Suits 4x4 & 4x2 (Excludes Under Protection Kit) | 2002 to 2007 | FF = Suits Flared Models | BU21-3522 | |||

Rodeo - RA7 - Suits 4x4 & 4x2 | 2007 to 2011 | FF = Suits Flared Models | BB = Requires Bumper Cut | BU21-3513 | BU21-36631Discontinued once stock is exhausted |

D-Max - TFS40 - 4x4 | Mid 2020 on | BB = Requires Bumper Cut | BU21-35562Superceded once stock is exhausted, please see specific vehicle page | BU21-5732 | BU21-37331Discontinued once stock is exhausted | |

D-Max - TFS85 - Suits 4x4 & 4x2 (Pre Face-Lifted Models Only) | 06/2012 to Early 2017 | BU21-5529 | BU21-5685 | |||

D-Max - TFS85 - Face-Lift Models | Early 2017 on | BB = Requires Bumper Cut | BU21-37191Discontinued once stock is exhausted | |||

D-Max - TFS85 - Face-Lift Models | Early 2017 to Mid 2020 | BB = Requires Bumper Cut | BU21-5547 | BU21-37182Superceded once stock is exhausted, please see specific vehicle page | ||

D-Max - TFS85, TFS77 - Suits 4x4 & 4x2 | 2007 to 06/2012 | FF = Suits Flared Models | BB = Requires Bumper Cut | BU21-3513 | BU21-36631Discontinued once stock is exhausted | |

MU-X - UCS40 | Mid 2021 on | FF = Suits Flared Models | BU21-3738 | |||

MU-X - UCS85 - Suits 4x4 & 4x2 | 2012 to Early 2017 (Pre-Facelift Models Only) | FF = Suits Flared Models | BU21-3699 | |||

MU-X - UCS85 - Suits 4x4 & 4x2 Face-Lift Models | 2017 on | FF = Suits Flared Models | BB = Requires Bumper Cut | BU21-5547 |

BT-50 - TF | Mid 2020 on | FF = Suits Flared Models | BB = Requires Bumper Cut | BU39-5563 | BU39-5740 | BU39-37411Discontinued once stock is exhausted |

BT-50 - UN - Suits 4x4 | 2007 to 09/2011 | FF = Suits Flared Models | BB = Requires Bumper Cut | BU39-3501 | ||

BT-50 - UP/UR - Suits 4x4 & 4x2 | 10/2011 to 03/2018 | FF = Suits Flared Models | BB = Requires Bumper Cut | BU39-5530 | BU39-5694 | BU39-36821Discontinued once stock is exhausted |

Challenger - PB, PC - Excludes Face-Lifted Models | 2009 to 06/2013 | FF = Suits Flared Models | BB = Requires Bumper Cut | BU43-3502 | ||

Triton, L200 - ML - Suits 4x4 & 4x2 | 10/2006 to 08/2009 | FF = Suits Flared Models | BB = Requires Bumper Cut | BU43-3502 | ||

Triton, L200 - MN - Suits 4x4 & 4x2 | 09/2009 to 02/2015 | FF = Suits Flared Models | BB = Requires Bumper Cut | BU43-3503 | BU43-3693 | BU43-36531Discontinued once stock is exhausted |

Triton, L200 - MQ - Suits 4x4 & 4x2 | 03/2015 to 2018 | FF = Suits Flared Models | BU43-5540 | BU43-5704 | BU43-37051Discontinued once stock is exhausted | |

Triton, L200 - MR - Suits 4x4 & 4x2 | 2019 to 2024 | BB = Requires Bumper Cut | BU43-5553 | BU43-5730 | ||

Triton, L200 - MV - Suits 4x4 & 4x2 | 2024 on | BB = Requires Bumper Cut | BU43-5570 | BU43-5746 |

Navara, Frontier - D22, NP300 - Suits 4x4 & 4x2 | 2002 to 2022 | FF = Suits Flared Models | BU45-3517 | |||

Navara, Frontier - D23, NP300 - Suits 4x4 & 4x2 (Suits Thai Built Models Only) Must Also Fit Upgraded Coils When Bullbar Is Fitted - See 4x4 Suspension Fitment Guide | Initial Release Until 12/2020 | BB = Requires Bumper Cut | BU45-5539 | BU45-5700 | BU45-37011Discontinued once stock is exhausted | |

Navara, Frontier - D23, NP300 - Suits 4x4 & 4x2 (Suits Thai Built Models Only) Must Also Fit Upgraded Coils When Bullbar Is Fitted - See 4x4 Suspension Fitment Guide | Initial Release Until 12/2020 | BB = Requires Bumper Cut | BU45-5539 | BU45-5700 | BU45-37011Discontinued once stock is exhausted | |

Navara, Frontier - D23, NP300 - Suits 4x4 & 4x2 (Suits Thai Built Models Only) Must Also Fit Upgraded Coils When Bullbar Is Fitted - See 4x4 Suspension Fitment Guide | 2021 on | BB = Requires Bumper Cut | BU45-35612Superceded once stock is exhausted, please see specific vehicle page | BU45-37362Superceded once stock is exhausted, please see specific vehicle page | BU45-37371Discontinued once stock is exhausted | |

Navara, Frontier - D23, NP300 - Suits 4x4 & 4x2 (Suits Thai Built Models Only) Must Also Fit Upgraded Coils When Bullbar Is Fitted - See 4x4 Suspension Fitment Guide | 2021 on | BB = Requires Bumper Cut | BU45-35612Superceded once stock is exhausted, please see specific vehicle page | BU45-37362Superceded once stock is exhausted, please see specific vehicle page | BU45-37371Discontinued once stock is exhausted | |

Navara, Frontier - D40 - Suits 4x4 & 4x2 Hi-Rider (Excludes RX Single Cab and any V6 T/D) | 09/2005 to 2015 | BB = Requires Bumper Cut | BU45-3504 | BU45-36541Discontinued once stock is exhausted | ||

Navara, Frontier - D40 - Suits 4x4 & 4x2 Hi-Rider (Excludes Single Cab) | 05/2010 to 2015 | BB = Requires Bumper Cut | BU45-3526 | BU45-3692 | ||

Pathfinder - R51 - Suits 4x4 & 4x2 | 09/2005 to 04/2010 | FF = Suits Flared Models | BB = Requires Bumper Cut | BU45-3504 | BU45-36541Discontinued once stock is exhausted | |

Pathfinder - R51 | 05/2010 to 09/2013 | BB = Requires Bumper Cut | BU45-3526 | BU45-3692 | ||

Patrol - GU Series 1, 2, 3 (Y61) - Centre Under Protection Only | 1998 to 2004 | FF = Suits Flared Models | BU45-3519 | BU45-3690 | BU45-36691Discontinued once stock is exhausted | |

Patrol - GU Series 1, 2, 3 (Y61) - Coil Spring Models Only, Centre Under Protection Only. | 1998 to 2006 | FF = Suits Flared Models | BU45-3519 | BU45-3690 | BU45-36691Discontinued once stock is exhausted | |

Patrol - GU Series 4 on (Y61) - Centre Under Protection Only | 09/2004 on | FF = Suits Flared Models | BU45-3505 | BU45-3691 | BU45-36551Discontinued once stock is exhausted | |

Patrol - GU Series 4 on (Y61) - Coil Spring Models Only, Centre Under Protection Only. | 2006 on | FF = Suits Flared Models | BU45-3505 | BU45-3691 | BU45-36551Discontinued once stock is exhausted | |

Patrol - Y62 - Excludes TI-L Model | 2010 to 2016 | BU45-36731Discontinued once stock is exhausted |

Fortuner - N160, N156 - Suits 4x4 & 4x2 | 07/2015 to 08/2020 | FF = Suits Flared Models | BB = Requires Bumper Cut | BU59-3713 | BU59-37171Discontinued once stock is exhausted | |

Fortuner - N160, N156 - Suits 4x4 & 4x2 | 09/2020 on | FF = Suits Flared Models | BB = Requires Bumper Cut | BU59-3742 | BU59-37431Discontinued once stock is exhausted | |

Hilux - N16, N17 - Suits 4x4, Excludes Under Protection Kit | 10/1997 to 2005 | FF = Suits Flared Models | BU59-3521 | |||

Hilux - Revo - N80 - Suits 4x4 | 2015 to 07/2018 | FF = Suits Flared Models | BU59-5552 | BU59-5728 | BU59-37071Discontinued once stock is exhausted | |

Hilux - Revo - N80 - Suits 4x4 | 08/2018 to 07/2020 | FF = Suits Flared Models | BU59-35522Superceded once stock is exhausted, please see specific vehicle page | BU59-5728 | BU59-37291Discontinued once stock is exhausted | |

Hilux - Revo - N80 - Suits 4x4 | 08/2020 to 11/2025 | FF = Suits Flared Models | BU59-5560 | BU59-5734 | BU59-37351Discontinued once stock is exhausted | |

Hilux - Vigo - N70 - Suits 4x4 | 04/2005 to 08/2011 | FF = Suits Flared Models | BU59-3510 | |||

Hilux - Vigo - N70 - Suits 4x4 | 09/2011 to 06/2015 | FF = Suits Flared Models | BU59-3527 | BU59-3695 | ||

LandCruiser - 70 Series | 1984 to 2007 | BU59-3515 | ||||

LandCruiser - 76, 78, 79 Series - 79 Series Double Cab, 76 Series Wagon, 78 Series Troopy | 2007 on | FF = Suits Flared Models | BU59-5747 | |||

LandCruiser - 76, 78, 79 Series - 79 Series Double Cab, 76 Series Wagon, 78 Series Troopy 2007 on | 2007 to 2023 | FF = Suits Flared Models | BU59-5506 | |||

LandCruiser - 76, 78, 79 Series - 79 Series Single Cab Models (Initial Release Only) | 2007 to 08/2016 | FF = Suits Flared Models | BU59-5506 | BU59-5747 | ||

LandCruiser - 76, 78, 79 Series - 79 Series Single Cab (Big Chassis) | 09/2016 to 2023 | FF = Suits Flared Models | BU59-5550 | BU59-5724 | BU59-37251Discontinued once stock is exhausted | |

LandCruiser - 80 Series - Suits Flared Models | 05/1990 to 1998 | BU59-3518 | BU59-36681Discontinued once stock is exhausted | |||

LandCruiser - 100 Series - Independent Front Suspension | 1998 on | BU59-3508 | BU59-36581Discontinued once stock is exhausted | |||

LandCruiser - 105 Series - Solid Front Axle | 04/1998 to 11/2007 | BU59-3507 | BU59-36571Discontinued once stock is exhausted | |||

LandCruiser - 200 Series - Initial Release & First Facelift Models | 2008 to 09/2015 | BU59-3696 | ||||

LandCruiser - 200 Series - Required For Models With O.E.M. Headlight Washers | 2008 to 2021 | |||||

LandCruiser - 200 Series - 3rd Generation (Also Suits Models with Headlights Washers) | 10/2015 on | BB = Requires Bumper Cut | BU59-35452Superceded once stock is exhausted, please see specific vehicle page | BU59-5714 | ||

LandCruiser - 300 Series | 2021 on | BB = Requires Bumper Cut | BU59-5565 | BU59-5744 | ||

LandCruiser Prado - 90 Series | 1996 to 2003 | FF = Suits Flared Models | BU59-36741Discontinued once stock is exhausted | |||

LandCruiser Prado - 120 Series | 2003 to 11/2009 | FF = Suits Flared Models | BU59-3511 | |||

LandCruiser Prado - 150 Series - Initial Release & Facelift Models | 10/2009 to 09/2017 | BB = Requires Bumper Cut | BU59-5512 | BU59-5697 | ||

LandCruiser Prado - 150 Series - Initial Release Only | 10/2009 to 09/2013 | BB = Requires Bumper Cut | BU59-36621Discontinued once stock is exhausted | |||

LandCruiser Prado - 150 Series - 3rd Generation Facelifted Models | 10/2017 on | BB = Requires Bumper Cut | BU59-5549 | BU59-5722 |

Amarok - Amarok - 4 Cylinder Initial Release Models | 2010 to 09/2016 | FF = Suits Flared Models | BB = Requires Bumper Cut | BU63-3523 | BU63-3680 | BU63-36751Discontinued once stock is exhausted |

Amarok - Amarok - 4 Cylinder Facelift Models | 10/2016 on & V6 Models - 2017 on | FF = Suits Flared Models | BB = Requires Bumper Cut | BU63-3548 | ||

Amarok - Amarok - 4 Cylinder Facelift Models | 10/2016 to 2022 & V6 Models - 2017 to 2022 | FF = Suits Flared Models | BB = Requires Bumper Cut | BU63-3720 |

SIDE STEPS & SIDE RAILS

Dobinsons range of 4x4 steel side steps and side rails are manufactured using 51mm (2”) steel tubing with a 2.0mm wall thickness and are formed using CNC computer controlled mandrell pipe benders to ensure that each bend remains smooth, kink free and has uniform tube wall thickness.