FAQ's

Frequently Asked Questions

-

Why Choose Dobinsons?

Dobinsons Spring & Suspension is a third generation, family owned Australian company that has built its reputation on exceptional quality and service. With the experience of three generations and over 60 years of suspension design, manufacturing expertise and experience in the 4x4 and suspension industries ensures that you’re in safe hands when dealing with Dobinsons.

As Dobinsons Spring & Suspension are a manufacturer, we have the ability to manufacture smaller quantities allowing us to offer a far greater range of springs than most other suspension companies. Dobinsons have the ability to offer multiple options for most vehicles (avoiding the ‘one size fits all’ approach) to provide high quality suspension kits designed to provide the best possible;

- Handling, Safety, Ride Quality, Load Carrying Capacity and Vehicle Control whether you are driving on road or off the beaten track.

Choose Dobinson’s for their reliable service, products designed to perform in any condition, as well as their knowledge and expertise to ensure the best experience for you and your vehicle.

-

Condition's of Sale & Warranty

Please see our Condition's of Sale page for all information regarding sales and warranty.

Warranty inquiries must be made at the place of purchase.

-

Problems with Parts?

If you encounter a problem with your Dobinsons products, please contact the original place where these goods/parts were purchased first.If this is unsuccessful please contact our head office throughThis email address is being protected from spambots. You need JavaScript enabled to view it. , providing as much information as possible. This may include;- Location of where goods/parts were purchased

- Date of when goods/parts were purchased

- Photos showing faulty parts or parts that are not performing as expected

- Any receipts or invoices as proof of purchase

-

How to Select Parts

Click here to download a short introduction on how to select the right parts for your vehicle.

-

How Much will Dobinsons Springs Lift/Lower My Vehicle?

The Dobinsons Spring and Suspension lifting and lowering heights are measured based on brand new vehicles and provide only an approximate guide on how much the vehicle will be be raised or lowered. In most cases the original springs on older, second hand vehicles may have sagged significantly compared to the original factory ride height. This may mean that the vehicle is required to be lifted higher or lowered slightly less than the amount stated in our corresponding catalogue.

Raised Springs

Raised Springs listed in the Dobinsons Coil Spring Catalogue (for any vehicle other than 4×4’s) will raise the vehicle approximately 30-40mm, in most cases, due to the vehicles suspension and steering geometry restraints. The Dobinsons 4×4 Suspension Catalogue lists the raised heights beside each part number for any particular vehicle.

Lowered Springs

Lowered Springs will generally lower a vehicle approximately 30mm unless noted otherwise. Super Lowered Springs will generally lower the vehicle approximately 50-60mm depending on your vehicle.

-

Are Dobinsons Parts able to be used in Conjunction with Original Parts?

Shock Absorbers

Dobinsons Shock Absorbers are designed and suited to lift kits up to 50mm/2″.

They are able to be used with original springs, but must be fitted in pairs.

Shock Absorbers that are designed for higher lift kits (anything over 50mm/2″) are not able to be used with original springs.

Leaf & Coil Springs

Dobinsons Springs that provide a lift of up to 50mm/2″ are able to be used with the original suspension on a vehicle unless noted otherwise.

However it is highly recommended that Dobinsons Shock Absorbers are also fitted at the same time to ensure sufficient wheel down-travel and to maintain optimum vehicle handling and safety characteristics.

Other Parts

Dobinsons Shackles, Shackle Pins, Polyurethane Bushes/Bush Kits and U-Bolts are able to be used with original suspension parts unless noted otherwise.

-

Are All Dobinsons Springs ‘Heavy Duty’?

Unless specified as ‘Comfort’ then all Dobinsons Springs have a heavier spring rate than the original springs. The amount that the spring rate is increased varies depending on the vehicle and also the design load of the spring. This means that the ride will be a little firmer than the factory ride in most cases.

Also in most cases, when raised springs are fitted the ride quality is improved due to reduced bottoming of the original suspension. Fitting a spring rated for constant load to a vehicle that does not have constant load will however make the vehicle ride firmer.

Dobinsons Suspension Systems have been designed and engineered to provide optimum ride quality whilst also ensuring exceptional;

- Vehicle Handling

- Performance

- Safety and

- Load Carrying Capacity

-

Springs Marked Left Hand Side & Right Hand Side

When fitting Dobinsons Coil Springs always check the small identification labels attached to the springs for the words ‘Left Side’ or ‘Right Side’.

When fitting Dobinsons Leaf Springs always check the markings on top of the main leaf for a ‘LH’ (Left Side) and ‘RH’ (Right Side)

LH/Left Side

To be fitted to the Left Hand side of the vehicle when seated in the vehicle facing the front of the vehicle.

RH/Right Side

To be fitted to the Right Hand side of the vehicle when seated in the vehicle facing the front of the vehicle.

-

My Vehicle Didn’t Lift the Expected Amount?

With popular secondhand 4x4 vehicles, it is common that they are already fitted with raised suspension kits. By providing the centre of hub to bottom of wheel arch/flare measurements to your local Dobinsons store they will be able to confirm if your vehicle has been lifted to the expected height.

The most common problem with vehicles lifting more or less than expected is due to incorrect part selection. In most cases, the incorrect spring has been chosen to suit the required application. It is also common in a lot of cases that springs are chosen originally for a vehicle with little to no constant additional load, then as more accessories are added to the vehicle the spring is no longer suitable for the application and different springs are now required.

This causes the vehicle owner to believe the springs have sagged, however it is the case that the springs are not designed for the additional load added, and if the additional load is removed the springs will return to the original height.

Dobinsons Springs once fitted may settle approximately 5mm in the first few weeks after being fitted but will not settle any further afterwards.

-

My Vehicle is Lopsided?

If you think your vehicle may be lopsided there are some checks that can be done to find out the cause.

Firstly, it is crucial that the vehicle is checked on a perfectly flat and level surface. Move the vehicle forward and backward a few time with the wheels straight to ensure the vehicle is not torqued to one side. The vehicle can then be assessed by measuring between the centre of the wheel hub to the bottom of the vehicle guard/flare. It is acceptable for a vehicle to have a difference of up to 12mm left to right (In fact it is common for vehicles like the Landcruiser 200 Series to have a variation of over 20mm from the factory.)

As Dobinsons Springs are manufactured to conform to the highest quality standards, and as all springs are 100% scragged it is extremely rare for Dobinsons springs to sag. Before removing the springs to check the free height there are a number of things that should be checked first;

Have the springs been fitted to the correct side?

See FAQ - Springs Marked Left Hand Side and Right Hand Side

Is there any additional load on the vehicle distributed evenly?

For example; is there a large toolbox/machinery/water tank/aftermarket fuel tank etc. fitted to one side of the vehicle?

Fuel Tank

One some vehicles such as Toyota Landcruisers and Nissan Patrols the fuel tanks are fitted on one side of the vehicle – it is a good idea to measure the vehicle with a full tank and an empty tank as this can also cause the vehicle to sit slightly lower on one side.

KDSS Sway Bar Systems

It is important to ensure correct fitment and re-setting of the KDSS system on vehicles such as the 200 Series Landcruiser as this can cause the vehicle to be pulled down on one side.

Damaged Shock Absorbers

A jammed or seized shock absorber can also cause a vehicle to sit un-level.

Damaged Sway Bar

Bent and damaged sway bars may also cause the vehicle to be pulled to one side.

Damaged Shock Absorber Bushings

On some independent coil over type suspension systems, worn or damaged bushes on one side may cause the vehicle to sit lopsided.

Damaged Control Arms

Bent or damaged control arms may also cause vehicles to sit unlevel.

Damaged Cab Mounts

Damaged or collapsed cab mounts can cause a vehicle to sit unlevel.

Damaged or Bent Diffs

Damaged or bent diffs, and in some cases on trucks diff or axles that have been bent during the wheel alignment process can cause the vehicle to sit lopsided.

Damaged Spring Seats/Coil Towers

It is quite common, especially on the rear of Nissan Patrols to have the spring seats bend upward at the top or crack due to overloading which will cause the vehicle to sit unlevel. It is also common on leaf spring Toyota Hilux’s that the lower spring perch bends away causing the vehicle to sit unlevel.

Bent Chassis

This is quite uncommon and improbable but it is possible that a bent chassis from vehicle misuse or overloading can occur and is generally difficult to diagnose and the springs should be checked first.

-

Nissan Patrol & Toyota Landcruiser Steering Shake/Wobble

‘Steering Shake and Wobble’ is quite common on both Nissan Patrol and Toyota Landcruiser models with Solid Axles and is generally caused by worn parts and bushes, incorrect steering geometry, misaligned or unbalanced tyres, or a combination of all three.

Worn Bushes & Parts

This will in most cases not apply to new or near new vehicles.

It is recommended that first you check the vehicle for worn bushes and parts, as even if this is not the cause of the problem worn bushes and parts should be replaced to ensure vehicle safety. The following components should be checked;

- Panhard Rod Bushes (Both Ends)

- Radius Arm Bushes (Both Diff and Chassis Ends)

- Tie Rod Ends (Both Ends of the Tie Rod & the Drag Link)

- Wheel Bearing Tension & Condition can also be checked along with the Swivel Hub Bearings. (Please Note; These can also be shimmed to meet the factory requirements)

It is also a good idea to inspect the panhard rod mounts as it is also possible for the mount to crack at the chassis end. Installing a new steering damper can also help to reduce the shake, however it does not correct the whole problem.

Insufficient Positive Castor Angle

Castor angle plays a major part in vehicle straight line stability and helps the steering to return to centre. If the vehicles suspension has been raised, the required positive castor angle is reduced and the castor angle moves closer to zero, impairing the vehicles steering stability. A wheel alignment done by a reputable 4×4 wheel alignment centre can determine whether castor correction is required. Castor angle can be corrected by using a number of castor alignment products listed below;

- For vehicles lifted 0-25″, Dobinsons recommend either Rubber Castor Bush Kit RB59-522K or Polyurethane Castor Bush Kit PB59-503K

- For vehicles lifted 2.5 – 3.5″, Dobinsons recommend Polyurethane Castor Bush Kit PB59-503K

- For vehicles lifted 4″ and above, Dobinsons recommend either the drop box kit WA45-509k for the Nissan Patrol or Castor Plate Kits WA45-513K/WA59-514K

Misaligned/Unbalanced Wheels & Tyres

It is common for most owners of Nissan Patrols & Toyota Landcruisers that have a raised suspension kit fitted, to also fit aftermarket wheels with a larger diameter and different types of tyres. Different wheel offsets, and larger mud/more aggressive, all-terrain type tyres can be very difficult to balance correctly and are a common cause of steering shake. Having the wheels balanced or tested fitting the original tyres and wheels, or using a friends original tyres and wheels is a quick way to determine if this is causing the problem.

-

When & Why Should I Extend My Bump Stops?

This applies mainly to solid/beam axle type vehicles. Unless noted otherwise in the catalogue Dobinsons Suspensions lifts of up to 60mm/2.5″ will not require a bump stop extension. If the vehicle lift exceeds 60mm/2.5″ then it is important to check whether bump stop extensions are required. It is vital to extend the bump stops and reduce the bump stop gap when required to ensure that the coil spring and shock absorbers do not bottom out. Bottoming out of the coil spring and shock absorber is extremely dangerous and can cause immediate and irreparable damage to the vehicle.

To check if bump stop extension is required to protect the SHOCK ABSORBERS, it is best to remove the shock absorbers and springs from the vehicle, lower the vehicle down to the bump stops and measure the length between the shock absorber mounts and then remove 20mm from this measurement for bump stop ‘crush’. Compress the shock absorber until it bottoms and record this measurement. Calculate the difference between the measurements and ensure that the bump stop will touch at least 20mm before the shock absorber bottoms.

To check if bump stop extension is required to protect the COIL SPRINGS it is best to remove the shock absorbers and springs from the vehicle, lower the vehicle down to the bump stops and measure the length between the coil spring mounts (tip to tip) and then remove 20mm from this measurement for bump stop ‘crush’. Check the solid height of the coil spring by either ringing your local Dobinsons store to check OR by;

- Measuring the wire diameter

- Counting the number of turns

- Multiply the total number of turns by wire diameter and add one extra wire diameter.

Calculate the difference between the measurements and ensure that the bump stop will touch at least 20mm before the coil spring bottoms out.

-

When do I Need Alignment Products for my 4x4?

Dobinsons Spring & Suspension recommend that where applicable a Brake Proportioning Valve extension be fitted on all raised suspension kits over 25mm/1″ to allow factory braking performance to be maintained.

Independant Front Suspension Vehicles

- For suspension lifts up to 50mm/2″ generally no alignment parts are required. However some Suzuki 4x4 Vehicles may require camber adjustment bolts to maintain the factory wheel alignment specifications.

Solid/Beam Axle Type Suspensions

- For suspension lift kits up to 60mm/2.5″ castor correction of some form may be required. It is not essential for all vehicles but is highly recommended to ensure vehicle straight line stability.

- For suspension lift kits between 75mm/3″ and 90mm/3.5″ castor correction is required, and also adjustable panhard rods are highly recommended. For customers wanting to maximise the off-road performance extended sway bar links and extended brake lines are also recommended. Extending the vehicles bump stops and driveshaft modification may also be required depending on the application.

- For suspension lift kits exceeding 90mm/3.5″ considerable alignment parts are required. Castor correction, adjustable panhard rods, sway bar extensions, extended bump stops, extended brake lines, gearbox spacing, driveshaft modification, adjustable/modified rear trailing arms and adjustable steering arm modifications are required along with other driveline, suspension and steering modifications which may also be required.

-

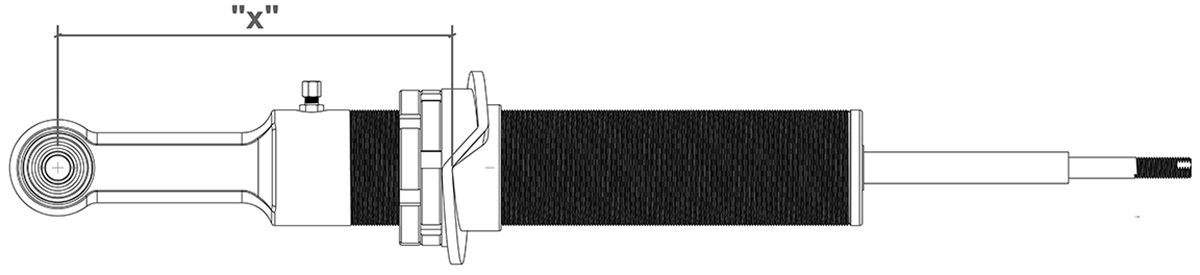

OEM Spring Seat Heights for Height Adjustable Struts

About Us

About Us

WHO WE ARE

Since our establishment in 1953, we have been at the forefront of Leaf and Coil Spring Manufacturing, specializing in the supply of Suspension Components. With several generations of family ownership and extensive experience, we've emerged as a leader in the global Spring Industry, integrating years of knowledge into our products.

Our success is rooted in delivering high-quality products, leveraging technical expertise, and utilizing state-of-the-art equipment to ensure professional service and performance.

WORLD'S LARGEST RANGE

We pride ourselves on having the world’s largest range of 4x4 spring and suspension componentry at Dobinsons Spring & Suspension. You can explore this extensive range through our online catalogues or by making selections online.

Our quality of design and manufacture is what sets us apart from our competitors, if not the price. We manufacture and repair a broad range of springs and sell a comprehensive range of suspension components.

At Dobinsons Spring & Suspension, we have been exporting our products to different parts of the world, and our name has become synonymous with quality in these countries.

SPRING SPECIFICATIONS

With an extensive database of over 13,000 spring specifications, we utilize advanced computerized spring design programs to ensure accurate and professional results.

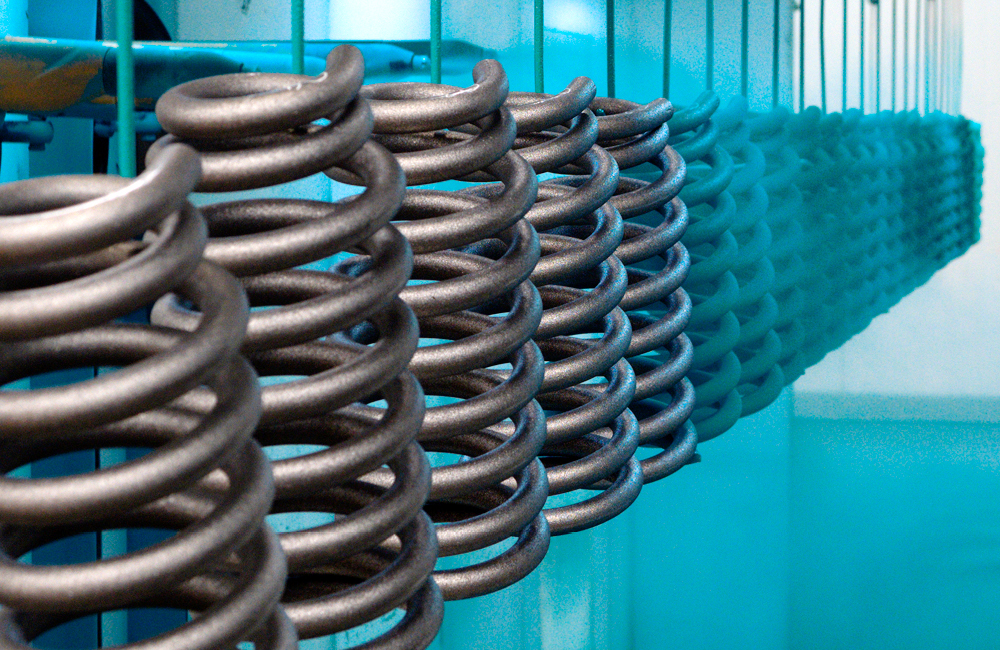

OUR FACTORY

Our Rockhampton factory covers over 4000m², consisting of a leaf spring production line, a coil spring production line and two large stock holding warehouses. There are thousands of parts kept in stock, including Coil Springs, Leaf Springs, Torsion Bars, Shock Absorbers, Greasable Shackle Kits and Pins, U-Bolts, Polyurethane Bushes, Centre Bolts, Castor Wedges & 4x4 Accessories. It also includes a fully equipped service department dedicated to removing and replacing all types of suspension componentry on passenger vehicles, 4x4 vehicles and trucks.

Our History

Established 1953

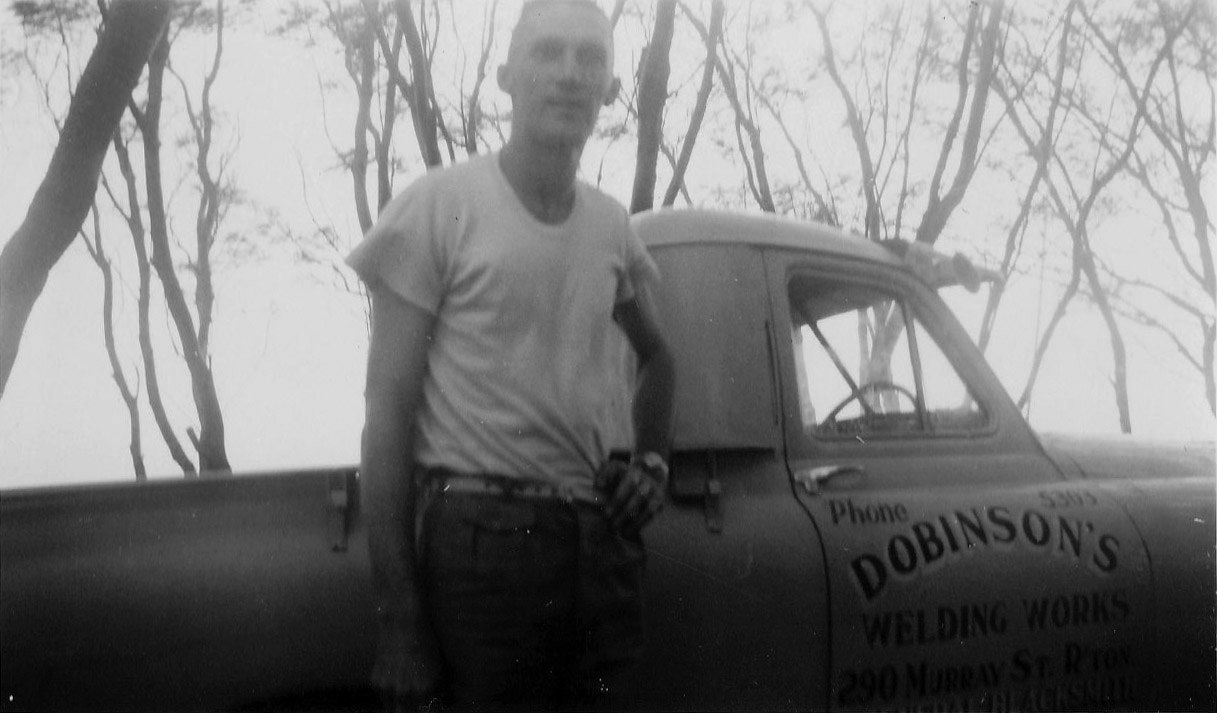

Throughout the 1940’s and early 1950’s Reg Dobinson, a hard working blacksmith, earned a well deserved reputation as an exceptional tradesman and expert spring repairer.

He began perfecting his spring repair and manufacture skills at the Queensland Railway and as a result the demand for his expertise grew. As time went on he began to specialise in spring repair and manufacture, and it led him to take on further weekend work for friends, repairing springs.

Reg’s keen eye for quality, attention to detail and his passion for blacksmithing and spring repair soon saw Reg spend all of his spare time working.

In 1953, having more work than he was able to handle, Reg founded ‘Dobinsons Welding Works’ (now known as ‘Dobinsons Spring & Suspension’) under a tamarin tree in the backyard of his Rockhampton home.

The next few decades saw the business grow exceptionally as Reg began specialising in the repair and the manufacture of springs for Rockhampton and surrounding areas.

With a huge demand for his quality work, Reg was soon working up to 18 hours a day, 7 days a week - without taking holidays for years at a time.

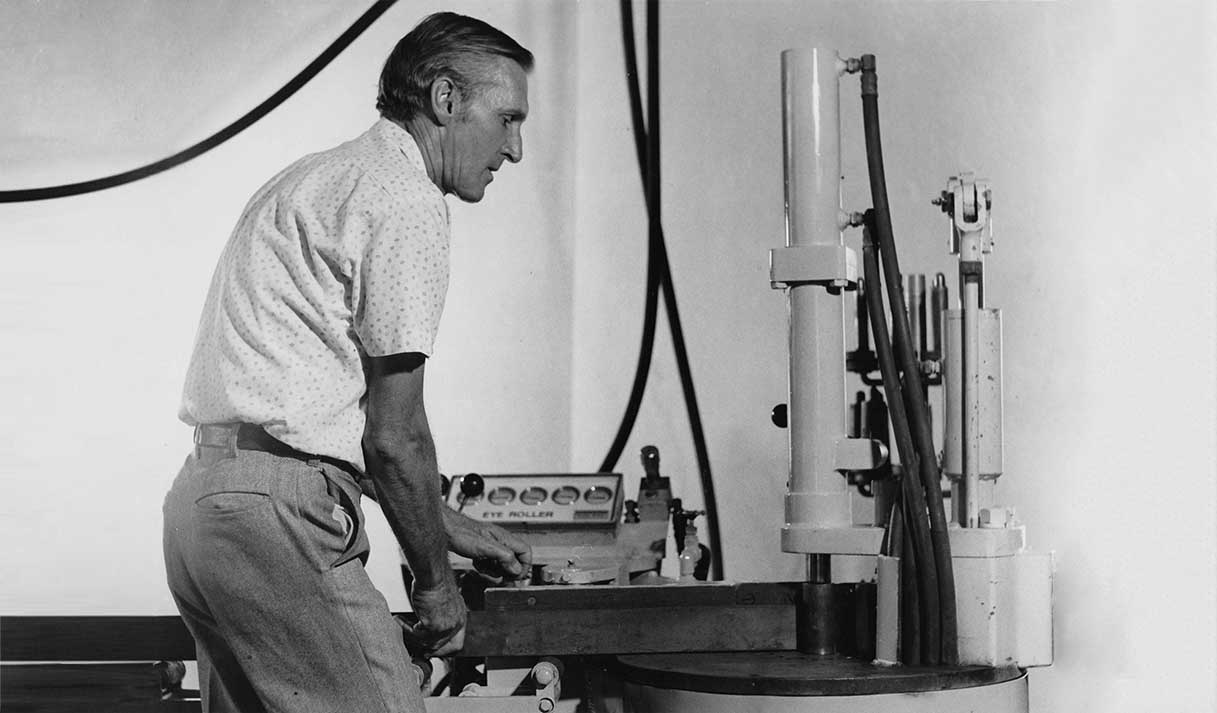

An innovator and a man ahead of his time, Reg purchased Central Queensland’s very first computer in the mid 60’s to improve efficiency. He also began to manufacture his own machinery such as a leaf spring eye roller - designed, engineered and built by Reg himself, utilising manufactured parts and hydraulics taken from ex-warplanes.

In the late 70’s, Reg’s sons Glen and Keith Dobinson joined the growing family business and immediately showed the same passion and expertise in spring repair and manafacturing, allowed Reg’s work load to be shared. With fresh eyes and more hands, Dobinsons began to distribute their quality products throughout Australia.

1958

Reg Dobinson with Dobinsons Welding Works first Company Vehicle.

1977

Reg Dobinson demonstrating his new invention, the ‘Leaf Spring Eye Roller’.

Built On Pride

Our success throughout the Australian market sparked our desire, as Reg and his sons, to share our top-quality products with the world.

In the mid-1980s, we exported our first order. While we now export to over 50 countries worldwide, in a time before fax machines were prevalent and the Internet existed, this meant a trip down to the local post office to purchase international phone books to find international distributors and to receive international orders.

In 1991, we moved to our current location in Rockhampton, and in 1994, Reg retired, leaving Glen and Keith as directors of our ever-growing company.

In the mid-'90s, our vision led us to design and build an entire coil spring manufacturing line, and we began producing world-class coil springs from our Australian production facility.

In the late '90s, with over 40 years of spring and suspension experience already under our belt, we began designing, developing, and distributing our own range of 4x4 shock absorbers.

In the early 2000s, Glen and Keith’s children began working in the family business, and with a shared passion for the suspension industry and 4x4’s, our company continued to grow.

In 2009, we began the research, development, and testing of our range of 4x4 accessory products, which have earned a reputation as high-quality 4x4 products that complement our extensive range of suspension products.

Over 60 years on, and three generations later, our Rockhampton production and warehousing facility has grown to over 8,000 square meters. We now have over 5 major warehousing distribution facilities across Australia with an Australia-wide dealer network, as well as distributors in over 50 countries worldwide.

[fa6-solid--chevron-up]

[fa6-solid--chevron-up]

Murray Street

Hollingsworth Street

[fa6-solid--chevron-down]

[fa6-solid--chevron-up]

[fa6-solid--chevron-up]

Hollingsworth Street

Contact Us

Contact Us

-

Rockhampton

(Head Office) -

Brisbane

-

Sydney

-

Melbourne

-

Adelaide

-

Perth

-

International Sales

(Export Department) -

USA

-

Middle East

-

Panama

58 Hollingsworth Street,

NORTH ROCKHAMPTON QLD 4701

-23.3458277,150.5051782

Dobinsons Rockhampton

Head Office

TRADING HOURS

| Monday | 7.30 am - 5.00 pm |

| Tuesday | 7.30 am - 5.00 pm |

| Wednesday | 7.30 am - 5.00 pm |

| Thursday | 7.30 am - 5.00 pm |

| Friday | 7.30 am - 5.00 pm |

| Saturday | Closed |

| Saturday | Closed |

| Public Holidays | Closed |

Send Us a Message

30 Kremzow Road,

BRENDALE QLD 4500

-27.3150285,152.9647484

TRADING HOURS

| Monday | 8.00 am - 5.00 pm |

| Tuesday | 8.00 am - 5.00 pm |

| Wednesday | 8.00 am - 5.00 pm |

| Thursday | 8.00 am - 5.00 pm |

| Friday | 8.00 am - 5.00 pm |

| Saturday | Closed |

| Saturday | Closed |

| Public Holidays | Closed |

Send Us a Message

Unit 2/63 Hartley Road,

SMEATON GRANGE NSW 2567

-34.0430532,150.7628323

TRADING HOURS

| Monday | 8.00 am - 5.00 pm |

| Tuesday | 8.00 am - 5.00 pm |

| Wednesday | 8.00 am - 5.00 pm |

| Thursday | 8.00 am - 5.00 pm |

| Friday | 8.00 am - 5.00 pm |

| Saturday | Closed |

| Saturday | Closed |

| Public Holidays | Closed |

Send Us a Message

Unit 1/13a Abbotts Road,

DANDENONG SOUTH VIC 3175

-38.0317224,145.2177215

TRADING HOURS

| Monday | 8.00 am - 5.00 pm |

| Tuesday | 8.00 am - 5.00 pm |

| Wednesday | 8.00 am - 5.00 pm |

| Thursday | 8.00 am - 5.00 pm |

| Friday | 8.00 am - 5.00 pm |

| Saturday | Closed |

| Saturday | Closed |

| Public Holidays | Closed |

Send Us a Message

25 Barndioota Road,

SALISBURY PLAIN SA 5109

-34.7671002,138.6628087

TRADING HOURS

| Monday | 8.00 am - 5.00 pm |

| Tuesday | 8.00 am - 5.00 pm |

| Wednesday | 8.00 am - 5.00 pm |

| Thursday | 8.00 am - 5.00 pm |

| Friday | 8.00 am - 5.00 pm |

| Saturday | Closed |

| Saturday | Closed |

| Public Holidays | Closed |

Send Us a Message

1/6 Oxleigh Drive,

MALAGA WA 6090

-31.8530137,115.8862318

TRADING HOURS

| Monday | 8.00 am - 5.00 pm |

| Tuesday | 8.00 am - 5.00 pm |

| Wednesday | 8.00 am - 5.00 pm |

| Thursday | 8.00 am - 5.00 pm |

| Friday | 8.00 am - 5.00 pm |

| Saturday | 8.00 am - 12.00 noon |

| Saturday | Closed |

| Public Holidays | Closed |

58 Hollingsworth Street,

NORTH ROCKHAMPTON QLD 4701

-23.3458277,150.5051782

TRADING HOURS

| Monday | 7.30 am - 5.00 pm (AEST) |

| Tuesday | 7.30 am - 5.00 pm (AEST) |

| Wednesday | 7.30 am - 5.00 pm (AEST) |

| Thursday | 7.30 am - 5.00 pm (AEST) |

| Friday | 7.30 am - 5.00 pm (AEST) |

| Saturday | Closed |

| Saturday | Closed |

| Public Holidays | Closed |

10311 NW 62nd Street,

DORAL, FLORIDA 33178

25.8295047,-80.3658562

TRADING HOURS

| Monday | 9.30 am - 5.30 pm |

| Tuesday | 9.30 am - 5.30 pm |

| Wednesday | 9.30 am - 5.30 pm |

| Thursday | 9.30 am - 5.30 pm |

| Friday | 9.30 am - 5.30 pm |

| Saturday | Closed |

| Saturday | Closed |

| Public Holidays | Closed |

13 4A Street

Ras Al Khor Industrial Area 2

DUBAI, UNITED ARAB EMIRATES

25.1826441,55.3488412

TRADING HOURS

| Monday | 9.30 am - 5.30 pm |

| Tuesday | 9.30 am - 5.30 pm |

| Wednesday | 9.30 am - 5.30 pm |

| Thursday | 9.30 am - 5.30 pm |

| Friday | 9.30 am - 5.30 pm |

| Saturday | Closed |

| Saturday | Closed |

| Public Holidays | Closed |

Parque Industrial,

Galera Dobinsons,

Calle Primera, Panamá, Panama

9.0132608,-79.4816654

TRADING HOURS

| Monday | 9.30 am - 5.30 pm |

| Tuesday | 9.30 am - 5.30 pm |

| Wednesday | 9.30 am - 5.30 pm |

| Thursday | 9.30 am - 5.30 pm |

| Friday | 9.30 am - 5.30 pm |

| Saturday | Closed |

| Saturday | Closed |

| Public Holidays | Closed |

-

FIND A STOCKIST

Find your nearest store for expert assistance and advice.

-

CATALOGUES

Looking for a specific part, browse our catalogues. -

CONTACT US

Can't find what you're looking for?

Contact us today.

SHOCK ABSORBERS

Each Dobinsons shock absorber is designed specifically for the vehicle and application and is designed to perform best when matched with Dobinsons Coil Springs.